SORM - Safety Override Risk Management

Interlocks and Overrides, Critical Equipment and Barrier Management

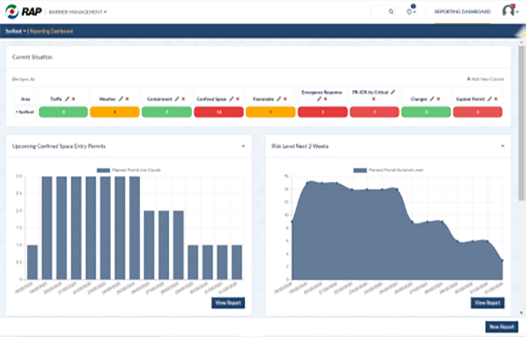

RAP’s SORM - Safety Override Risk Management solution offers visibility of current, future and historical permitting workload and highlights “overload risk” and provides additional dashboarding and reporting functionality specific to these in order to ensure operational risk management for process safety.

System | Features

Through the years Yokogawa RAP have enabled our customers to monitor critical aspects of their plant. These could be the monitoring of:

- Interlocks and Overrides (IOR’s)

- Management of critical valve downtime allowance such as for Pressure Relief testing (PR testing)

- Offline time for partial stroke work with emergency Shutdown Valves (EDS’s)

- Bypass line routing whilst the main line is closed for maintenance

Aside from monitoring the timeline of removed devices, we have also been asked to monitor:

- Downtime on critical alarms

- Monitoring line blind (or spade) insertion

- Air gap presence

The above examples have one thing in common, they are a change to the normal operating process and involve either the removal of or addition of a safety barrier within the system.

The isolation module from Yokogawa RAP sets the procedure for carrying out safe isolations and by bringing together our critical asset monitoring capability the updated Isolations module allows our users to benefit from an easy to use system and approach to barrier management to manage and monitor priority process barriers in real time, no matter what type they are for the duration that they are in place and to make sure that users are aware if barriers are not back to normal state in line with planned timeframes.

Linking to the isolation system as well as to the existing permits, the newly updated Isolations system from Yokogawa RAP is yet another example of how we assure smarter, safer working for operational excellence.

Key features include:

- Interlock and Override Tracking: Tracks permit work involving Interlocks and Overrides or other highly critical work items as set by the user

- Environmental Tracking: Tracks jobs that may be subject to environmental conditions

- Critical Equipment and Barrier Tracking: Tracks permit work involving Pressure Relief or other highly critical work items as set by the user

- Expired Permits: Tracks expired & non-returned permits to improve site visibility or which ones, where and who still has them

Benefits

- Gain a full and quick understanding of site activities

- Enhanced understanding of sources of risk to prevent incidents and accidents

- Reduce risk exposure

- Log all Interlocks and Overrides

- Risk Assess individual cases using standard or customised techniques

- Establish which Safety Barriers you wish to consider and monitor and control any threats to them

- Fully competence based

- Can be used for any temporary change

- Fully configurable assessment of risk for every change